Food systems impacts of COVID 19

Food systems impacts of COVID 19

Posted by Steve Guilbert

23 September 2020

By Prof. Michael Winter

A meat theme to my blog this month and, in particular, a couple of stories that have come my way, one that shows that not all change and innovation is driven by COVID. There are other issues that still matter as well. The second is an example of an unexpected impact of COVID-induced dietary change.

First to sausages. Sausages are one of those foods that have done well in the market place as a result of COVID and the growth in home cooking. In August, the Evening Standard reported that food producer Cranswick had seen a surge in sales, of 24.8% in the 13 weeks up to June 27th compared to the same period in 2019. Some of that was because of new acquisitions so that the like-for-like increase in revenue was 19.2%. But it’s another sausage story that I want to highlight now. Alongside the challenge of dealing with COVID, there are other priorities that cannot, and should not, be forgotten, associated with climate change, biodiversity loss and environmental deterioration.

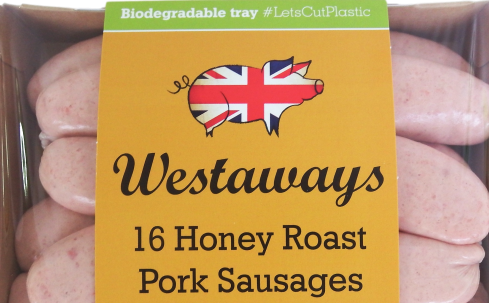

One issue that was receiving a great deal of attention during the months immediately prior to the pandemic was the scourge of plastic packaging. In attempting to reduce the use of plastics in the food sector, meat products pose a particular challenge because of the nature of the product. But a family-owned sausage manufacturer located just down the road from Exeter in Newton Abbot, Westaways, has pioneered a solution and in June started using the first certified compostable packaging for a retail chilled meat product in the UK.

In partnership with an Italian packaging company Fabbri Group, they have developed and introduced a new wrapping film certified to EN13432, the EU harmonized standard for compostable and biodegradable packaging. Quoted in the trade magazine, Meat Management, Charles Baughan Westaways MD, sums it up as follows: “Visit the meat and dairy produce aisles in most retailers and you are surrounded by plastic of many different types. Plastic is without doubt an easy solution to preserving and presenting food. However, I think most people realise and understand that not all packaging ends up where it should. My team wanted to develop a format for our sausages that meant wherever our packaging ended up it would degrade, leaving no harmful residues or microplastics behind.”

Scientists reading this will want to know which biodegradable route the firm has chosen to go down. Well it’s PBAT (Polybutyrate Adipate Terephthalate), a polymer that is broken down by microbial action. And here’s the twist – PBAT is partly derived from petrochemicals but is often added to other plant-derived bioplastics to improve biodegradability so that products comply with home composting criteria. As the Better Packaging Co, explains ‘when it comes to plant-based inputs there is a trade-off between renewability and compostability – the higher the % renewable, plant-based components the slower it is to compost!’ These issues certainly are complex! Don’t forget that plants used in purely plant-based plastics are likely to be commercially grown, maize for example, and therefore subject to all the environmental challenges associated with modern agriculture including, of course, its dependence on fossil fuels for fertilizers and fuel for agricultural machines. Bioplastics without PBAT require high heat industrial composting to break down. Without such heat, they only degrade over a very long timeframe, and in marine environments function similarly to conventional petroleum-based plastic, breaking down into micro-sized pieces, lasting for decades, and presenting a danger to marine life. And, given this project’s interest in the security of food supplies, plant based bioplastics have a knock-on implication for the amount of land devoted to food plants. Many would argue that PBAT remains a valid call given this wider context. And Westaways are to be applauded for their innovation and for pressing on with introducing a new packaging product at the height of the COVID pandemic.

For additional information on the food packaging issue see: UK Parliament POST Proposals to increase UK recycling of plastic food packaging by Peter Border.

My second story concerns wild venison. The Mail Online (21st September) report that a decline in wild venison consumption, already in evidence because of cheaper, farmed imports from New Zealand, Poland, Spain and Portugal, was exacerbated by the collapse in the restaurant trade due to COVID. With a glut of deer and no incentive for the usual culling, the deer population is growing at a time when the Government aspires to increase woodland coverage to help lock up carbon to combat climate change. Too many deer (and indeed too many grey squirrels) make it challenging to establish new woodland and also to properly manage existing woodland including through natural regeneration. Anyone who has ever visited a deer farm with existing woodland will know that deer, in sufficient concentration, like all grazing livestock, are not really compatible with natural regeneration or, indeed, optimal conditions for biodiverse woodland ground flora. So in the absence of natural predators, like wolves, deer management is essential and close integration with the food supply chain important. According to the Mail, citing the Game Dealers Association chairman Stephen Crouch, “600,000 deer need to be killed each year to control the UK’s population, which now stands at two million. But the amount stalkers are paid for carcasses has fallen from about £2.50 to £1 per kilo”. A Wild Venison Working Group, chaired by the Forestry Commission, with representation from stakeholders in woodland management, shooting, gamekeeping, and venison supply sectors, is promising a “Wild Venison Week” early in 2021 to promote consumption.